-40%

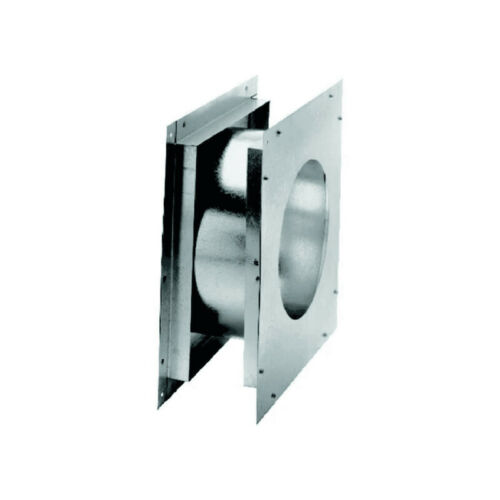

Duravent W2-606 6 Inch Double Wall Vent FasNSeal Series NEW in box

$ 15.83

- Description

- Size Guide

Description

DURAVENT W2-606 DOUBLE WALL VENT - NEW IN BOX, ONLY OPENED FOR PHOTOS. 6" DIAMETER 6" LENGTHMaterial Selection and Design

The FasNSeal®W2 Double+Wall Special Gas Vent System is manufactured under the most stringent quality control measures utilizing the latest production technology and know-how. FasNSeal® W2 is ideally suited for exhausting high efficiency, natural gas or propane fired heating equipment, where low flue gas temperatures can result in significant condensate formation within the vent system.

The

flue gas conduit (inner tube)

is made from AL29-4C, a super ferritic stainless steel designed for extreme resistance to chloride ion pitting, crevice corrosion and stress corrosion cracking, as well as general corrosion in oxidizing and moderately reducing environments. AL29-4C is an ideal choice for resisting deleterious effects of corrosive condensates created by partially or fully condensing natural gas and propane fired heating appliances. The Canadian Gas Research Institute confirmed that test results proved AL29-4C to be one of two “most corrosion resistant alloys of twenty candidate stainless steels evaluated for resistance to chloride-induced corrosion in condensing and partially condensing gas-fired appliances”. AL29-4C is a registered trademark of Allegheny Ludlum Corp.

The

Jacket (outer tube)

is manufactured from type 304 or type 430 stainless steel to provide long lasting performance and stability inside a building or when exposed to the outdoors.

The

air space

between the flue gas conduit and jacket is .5 inches, providing close clearances to combustibles, reasonable outside dimensions and an additional heat shield or margin of safety where needed.

FasNSeal® W2 has been tested and is listed by Underwriters Laboratories, Inc.* to UL 1738 and ULC-S636-95 safety standards. When installed according to DuraVent's installation instructions, FasNSeal® W2 meets all test requirements for horizontal and vertical; interior or exterior installations.

FasNSeal® W2 Is Built For Performance

Proven in our single wall system since 1997, all FasNSeal® products feature a smooth weld seam inside and out that is completely shielded during the TIG welding process. Contamination or molecular changes in the weld seam are avoided; no fillers are used in the welding process. Tube ends are formed under the most stringent quality standards to guarantee a perfect fit every time and to avoid built-in stress points or weak areas.

FasNSeal® W2 Applications

FasNSeal® W2 is a Special Gas Vent and Gas Vent Connector, designed for use on natural gas or propane-fired appliances listed as Category II, III and IV or in Canada Type BH Gas Vent Systems having a maximum operating temperature of 480 degrees F and maximum rated positive pressure of 6” water column (tested at 15” water column! ). FasNSeal® W2 provides venting for high efficiency gas boilers, furnaces, booster heaters, pool heaters, water heaters, unit heaters or tankless water heaters and is available in 3” -10”, 12”, 14” ,16”, 18", 20", 22" and 24" nominal flue gas conduit diameters. FasNSeal® W2 may also be used as a vent for Category I, natural gas or propane-fired heaters. (See installation instructions for details). FasNSeal® W2 must be sized according to the heating appliance manufacturer’s instructions, NFPA 211, NFPA 54, The National Fuel Gas Code ANSI Z223.1 and any other relevant local building codes and regulations (see installation instructions for details!). FasNSeal® W2 Features Built-in Gaskets And Mechanical Locking Bands The flue gas conduit of every vent length and component (inner tube) features a built-in gasket in its female-end to seal each joint. An integrated mechanical